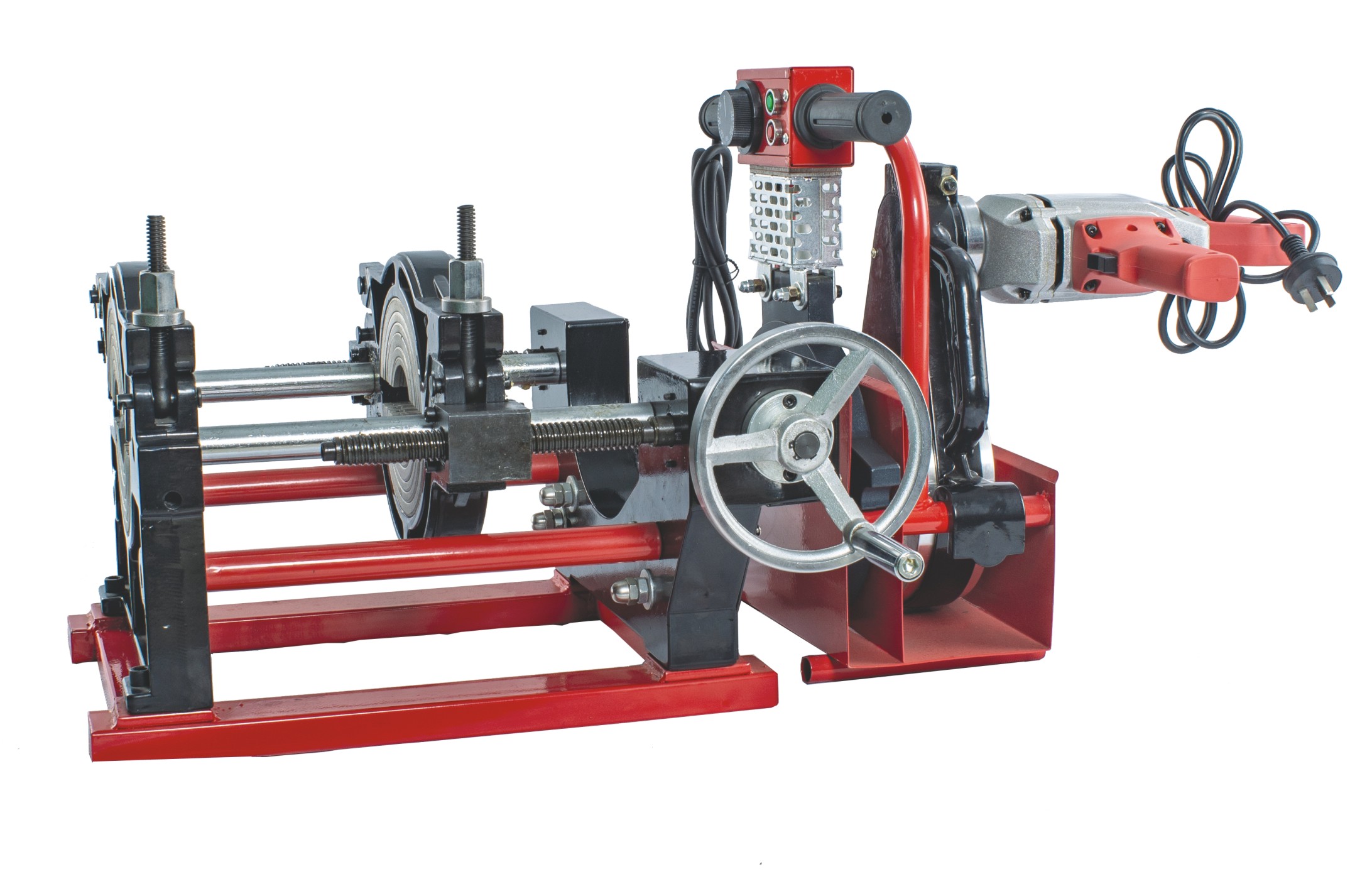

1. High power milling cutter, mirror cutter disk, strong motor,

high concentricity, smooth milling.

2. High-power Bosch drill is adopted for milling motor, which is

strong and strong without slipping

3. The milling cutter is equipped with a limited position switch,

which can be rotated only when placed in the frame to prevent

accidental injury.

Preparation

Preparation for welding HDPE Pipe manual Butt Fusion Welding

Machine 1. Before operation, all equipment parts shall be placed on

a stable and dry place. 2. Confirm that the power supply used meets

the requirements of the equipment, the equipment is in good

condition, and the electrical circuit is not damaged; the detection

indicator works normally, the milling cutter blade is sharp, and

the parts and operating tools are complete. 3. Replace the required

fixture according to the outer diameter of the welded pipe.

Notice

Common problems of various components of the hot melt machine when

connecting PE pipes: 1. The maximum temperature of the heating

plate of the heating plate reaches 250 °C, so be sure to pay

attention to the following categories: ① Wear anti-cutting gloves ②

Pay attention to the safety precautions of the actual operating

staff. After the welding is completed, it should be placed in a

special heating plate support frame. ③ The heating plate should be

cooled before transportation to prevent fire. ④ After the electric

welding is completed, put the heating plate in a safe area to

prevent others from accidentally touching the burn. ⑤ Grasp the

door handle when lifting the heating plate. Do not disconnect the

switching power supply of the heating plate ⑧ Remember not to touch

the heating plate with force 2. Milling cutter ① Before cutting the

pipe (piece), make sure that the end face of the pipe (piece) is

clean and free of dirt to prevent damage to the cutting blade ②

Pipe (piece) cutting After the end, after the milling cutter disc

stops rotating, take out the milling cutter disc and store it. ③

Hold the door handle when obtaining the milling cutter disc. ④ The

milling cutter disc can only be rotated when it is installed on the

welding frame. Do not arbitrarily adjust the toggle switch of the

milling cutter. 4. Frame ① Check the parts/materials to be welded

to ensure that they are accurately clamped on the frame , to ensure

the welding quality of electric welding. When heating, the actual

operating staff should stand off the welding machine moderately. ②

During electric welding, if the movable chuck and the fixed chuck

collide, it is not necessary to use the main gate of the welding

machine to shut down, only move the work The pressure adjustment

lever can open the chuck. ③ When transporting the rack, make sure

that the chucks are all tightened to prevent them from falling off.

FAQ

1. Who are we?

We are professional plumbing tools company located in Zhuji city of

China, we are close to Port Shanghai, Ningbo and Yiwu. We mainly

sell to North America, Europe and the Middle East countries. Our

client are tools wholesaler and comnpany for specific constrution

project such as fire fighting pipeline building etc.

2. How can we guarantee the quality?

We will test at least one pipes on every machine before shipping

out.

Some of our heavy duty models works well after even 7 or 8 years

according to our client feedback, for all of our machine we offer

one year warranty.

3. What can you buy from us?

All kind of pipe tools and plumbing tools, such as pipe welding

machine, pipe cutters, as well as the test pump.

4. Why should you buy from us not from other suppliers?

We focus on quality piping tools and machinery and service.

We have almost all kind of pipe tools, place order to us we can mix

various models in one shipment.

Speaking:English,Spanish,Japanese,Portuguese,German,Arabic,

French,Russian,Korean,Hindi,Italian

5. How long is the leadtime?

Since the voltage of machine motor are customized, usually the lead

time will be 30 days after payment.