STT50 Universal Electric Pipe Threading Machine 1/2″-2″ for pipe

Pipe threading machine is also called threading machine, electric

threading machine, pipe threading machine and so on. It is mainly

used for thread processing of steel pipe materials, and the

connecting threads are processed on the raw materials by cutting.

Before 1980, people usually used manual pipe thread twisting plates

to perform thread processing manually. After 1980, with the

progress of electrification, on the basis of manual pipe thread

twisting plate, an electric pipe threader was manufactured, which

greatly reduced the labor intensity and improved the processing

efficiency.

The threading machine is composed of a body, a motor, a chuck, a

die head, a chamfering device, a cutter frame, a knife feed device,

and a cooling system. There are generally two types of threading

machines in the market. One is a heavy-duty threading machine, all

made of aluminum alloy, with large weight, stable performance, and

high price. It is suitable for long-term projects and is not easy

to move. The other is a light threading machine, the lower part is

made of iron plate, the upper part is made of aluminum alloy, which

is small in weight, strong in flexibility, low in price, and low in

stability. It is suitable for projects with short construction

period and frequent flow.

Specifications

Model: STT50

Machining size: 1/2"-2" (Φ13-Φ50) for pipe

Motor power: 750W

Speed: 28rpm

G.W./N.W.: 75/63kgs

Packing size: 700*450*520mm

Standard Equipment

Quick-open die head

Dies set 1/2”-3/4”

Dies set 1”-2”

Support

Tools bag

Optional die head

Quick-open die head

Dies set: BSW ¼”, 3/8”, ½”, 5/8”, ¾”, 7/8”, 1”

Key words:pipe threading machine, electric pipe threading machine, Iron pipe

threading machine, steel pipe threader, stainless steel threading

machine, portable pipe threading machine, automatic pipe threading

machine

Technical data

| Product Name | STT50 Universal Electric Pipe Threading Machine 1/2″-2″ for pipe

And |

| Rotational speed of main shaft | 28 r/min/ |

| Model of die head | Die head for (1/2″-2″) |

| Scope of application | 1/2-2" |

| Power of motor: | 750w |

| Gross net weight | 75kg/66kg |

| Packing dimension | 700mm*450mm*520mm |

| Item | steel pipe threader |

| Key word | stainless steel pipe threading machine |

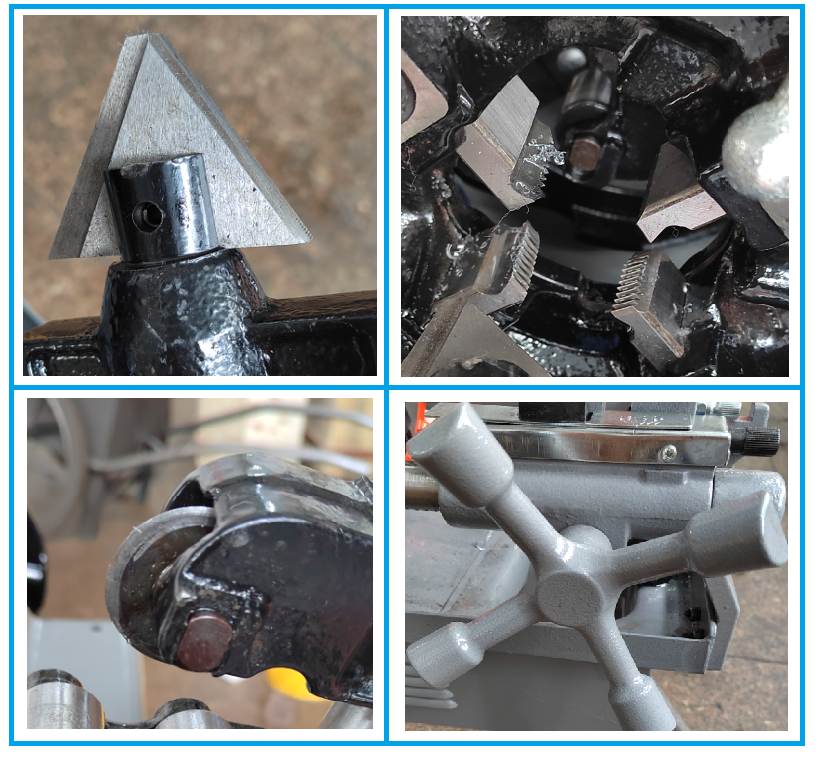

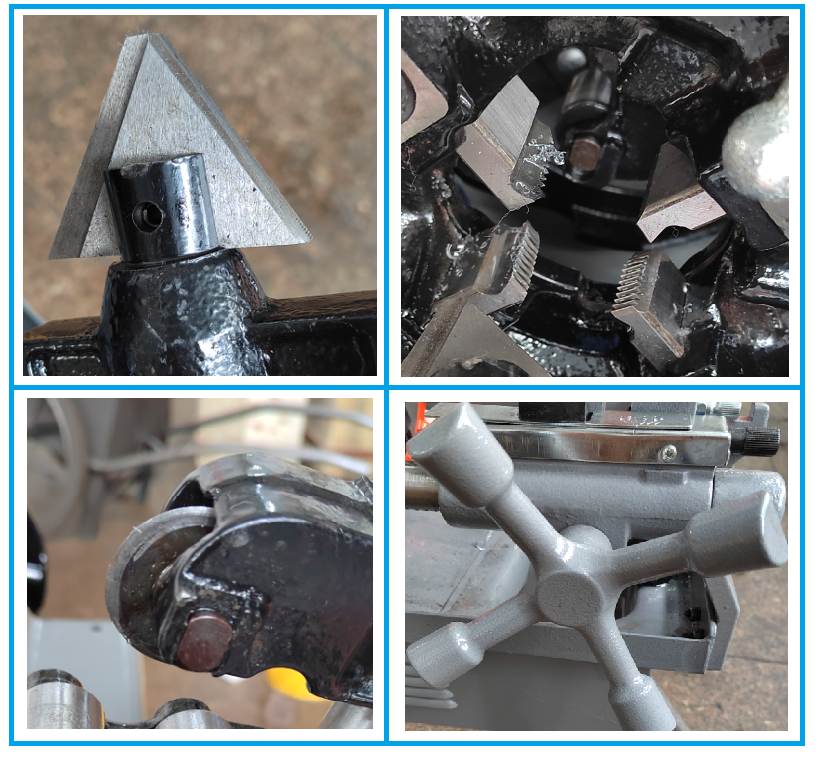

Detail photos

A pipe threading machine is a tool used to create threads on the

end of a pipe. There are two types of threading machines: electric

and manual. Both types use a die head to cut the threads, but the

way they power the die head is different.

Electric threading machines use an electric motor to rotate the die

head. The motor is connected to a gearbox that reduces the speed

and increases the torque. The gearbox then drives the spindle,

which rotates the die head. The die head is mounted on a carriage

that moves along the length of the pipe. The carriage is controlled

by a hand-held pendant that the operator uses to move the carriage

and start the threading process. Once the die head has cut the

threads, the operator reverses the carriage to remove the die head

from the pipe.

Manual threading machines, on the other hand, use a crank to rotate

the die head. The operator turns the crank by hand, which rotates

the spindle and the die head. The die head is also mounted on a

carriage that moves along the length of the pipe. The operator must

move the carriage by hand and start the threading process manually.

Once the threads are cut, the operator reverses the carriage to

remove the die head.

Regardless of the type of threading machine, the die head is the

most important component. The die head contains several dies that

are shaped like screws. The dies cut the threads into the pipe as

the die head rotates. The dies are held in place by a set of jaws

that are tightened around the pipe. The jaws are also part of the

carriage that moves along the length of the pipe.

In conclusion, a pipe threading machine is a tool used to create

threads on the end of a pipe. It does this by rotating a die head

that contains several dies that cut the threads into the pipe. The

machine can be either electric or manual, but both use a die head

mounted on a carriage that moves along the length of the pipe. The

operator controls the movement of the carriage and starts the

threading process either with a hand-held pendant or manually

turning a crank.

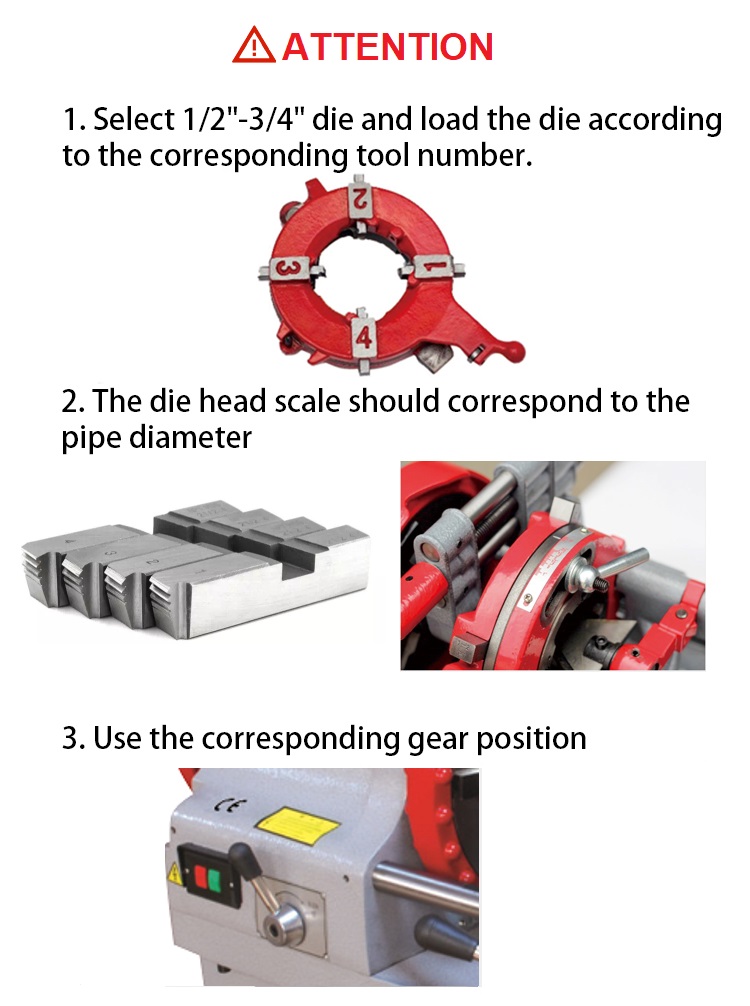

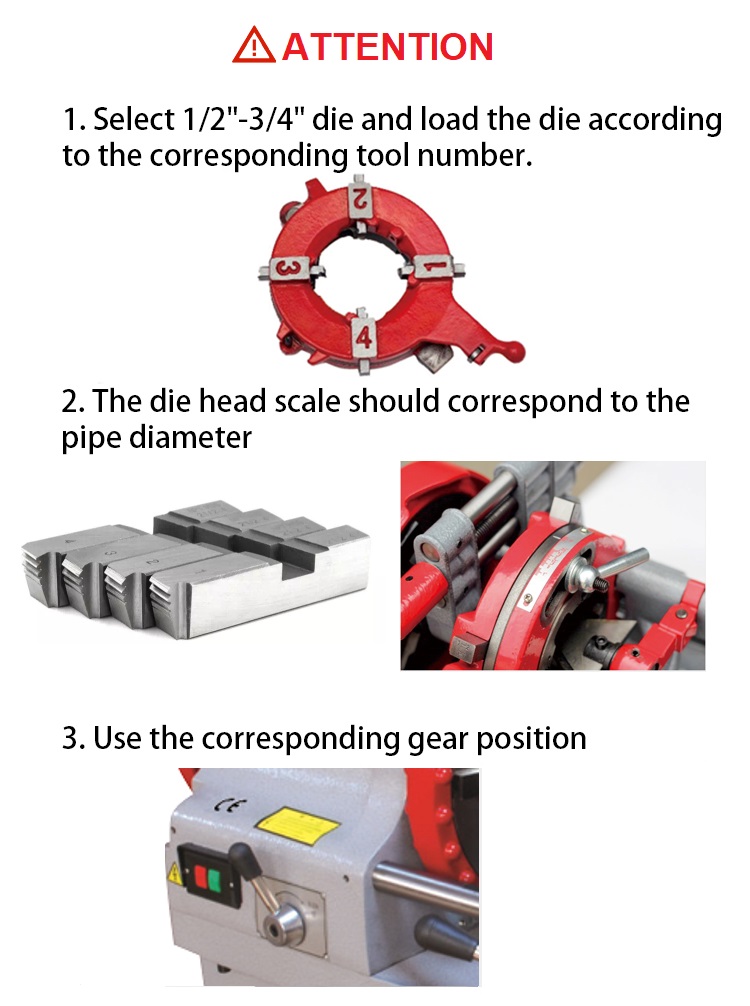

Important Notice

1. This machine shall be used with reliable grounding and

anti-creep device.

2. Children are prohibited from touching this machine to avoid

injury.

3. This machine shall not use the same socket with large-power

machines, such as electric welding machine.

4. Pipe clamps shall not be installed on the machine, to avoid

cracking of main components such as the cabinet.

5. Saponified solution shall not be used for cooling, such as

water.

6. When above 2½″ pipe thread is made, it is required to adopt the

low-gear processing mode,

7. When leaving factory, centrality of the machine has been

measured, but pipes on the market have certain ovality at present.

After machining, screw threads may be deep on one side and shallow

on the other side. If they affect use, please check the quality of

pipes.